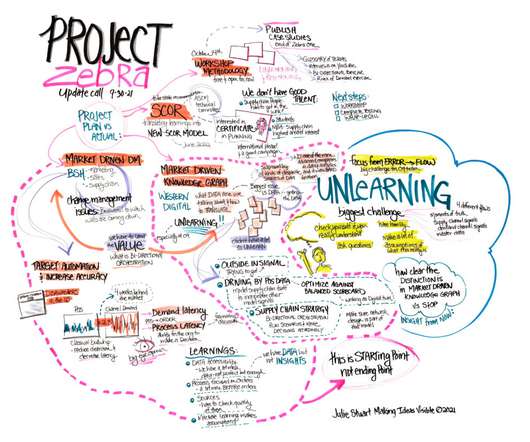

Outside-in Process Q&A

Supply Chain Shaman

FEBRUARY 26, 2024

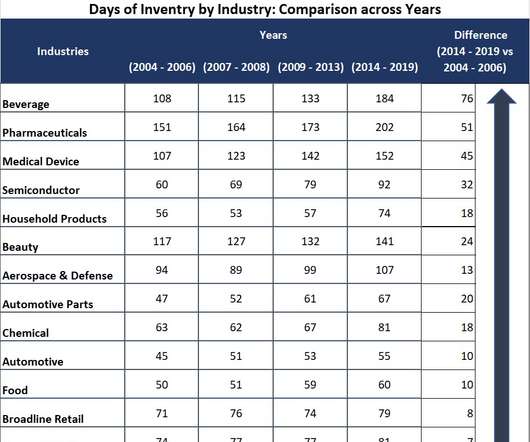

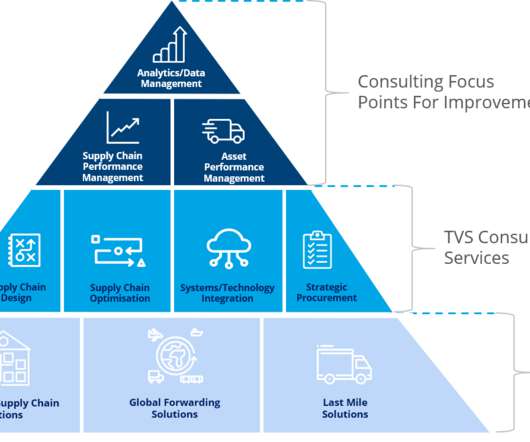

For example, in manufacturing, the shift in focus is away from OEE to focus on first pass yield and schedule adherence.) They implemented a simple planning technology with an outside-in channel-centric model (Ship to model definition). Using network design technologies calculate the form and function of inventory.

Let's personalize your content