The Forecasting Accuracy Bugaboo

Logistics Viewpoints

MARCH 27, 2023

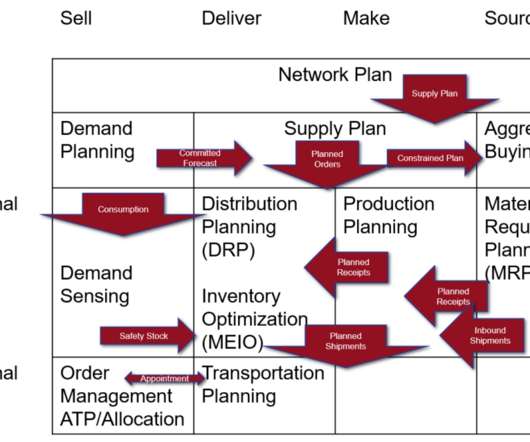

Demand forecasting is the process of making future estimations of how much of a given product will sell by location and time period. Organizations then convert those demand forecasts to the associated quantities of raw materials to purchase, goods to be manufactured, or finished products to ship.

Let's personalize your content