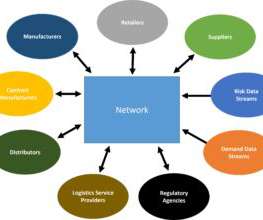

Direct Spend Management: A Checklist for Enabling Shared Value with Direct Suppliers

Logistics Viewpoints

OCTOBER 17, 2024

Access to Unique Process and Asset Capabilities: Some suppliers offer unique skills, technologies, or processes that are not available in-house or through other sources. Or they may have expertise in manufacturing processes and have flexible capacity to allow contract manufacturing for new product introduction.

Let's personalize your content