Elevating Inventory Management with Multi-Echelon Inventory Optimization

Logility

JUNE 5, 2024

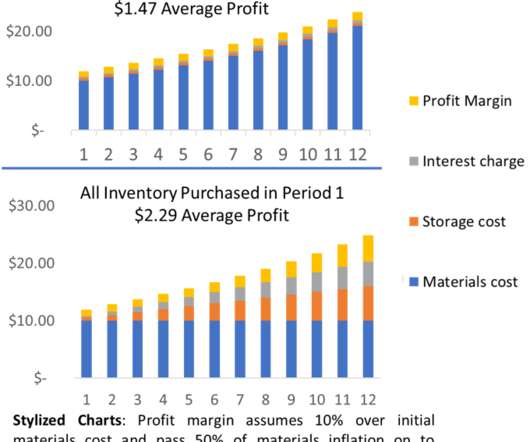

All these outcomes from multi-echelon inventory optimization translate into millions – and in some cases, billions – in working capital freed up from excess stock and carrying costs! The benefits extend far beyond just inventory reduction. And it’s not difficult to get started, as you may think.

Let's personalize your content