Editor’s Choice: It’s time for traditional inventory management to evolve!

Logistics Viewpoints

DECEMBER 14, 2022

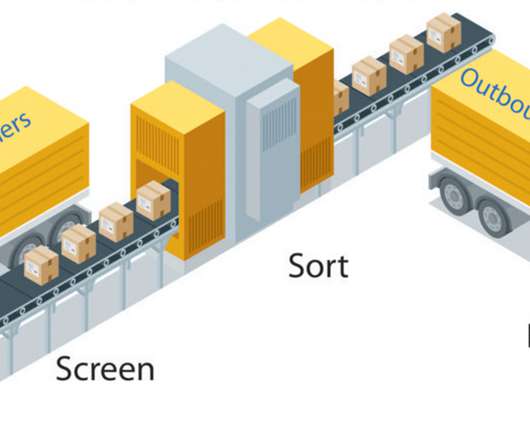

As a result, inventory managers have to explore new ways to cope with full warehouses. This new overflow strategy has mitigated inventory imbalance due to the scalability and mobility of transport equipment. The answer goes beyond standard inventory management. To read the full article, click HERE.

Let's personalize your content