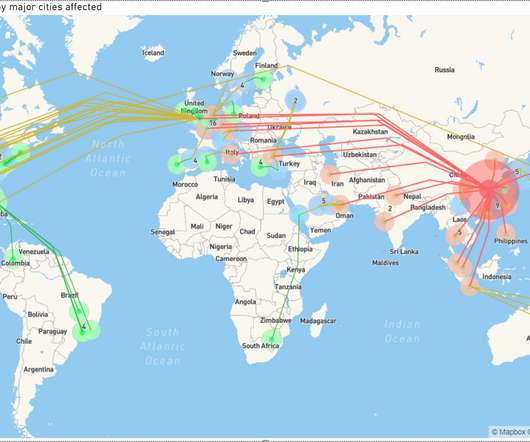

Global Production Activity Levels Unchanged In May But Provide Added Warning Signs

Supply Chain Matters

JUNE 5, 2023

What we found somewhat concerning was the indication that growth in manufacturing production accelerated to an 11-month high in May, and yet important leading indicators such as new business and new export orders have dropped to multi-month lows. That could signal even more added inventory exposures.

Let's personalize your content