The One Key Shift in Your Supply Chain and Procurement Strategies that can Drive Better Business Continuity and Resilience

Logistics Viewpoints

APRIL 6, 2023

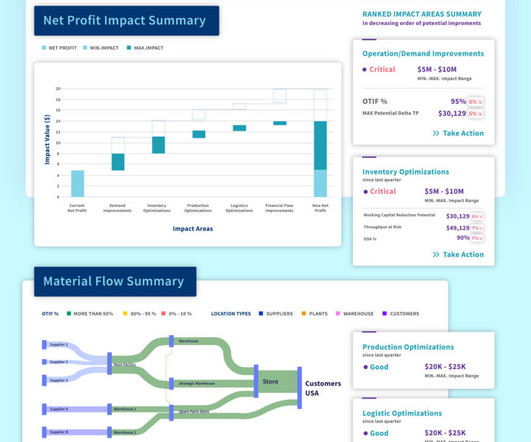

By working closely with suppliers, organizations can improve the quality and reliability of their in-bound supply chains, reduce costs, and increase their overall efficiency. The costs associated with purchasing these items hit the “operational expenses” components of the company’s financial statements.

Let's personalize your content