Outside-in Process Q&A

Supply Chain Shaman

FEBRUARY 26, 2024

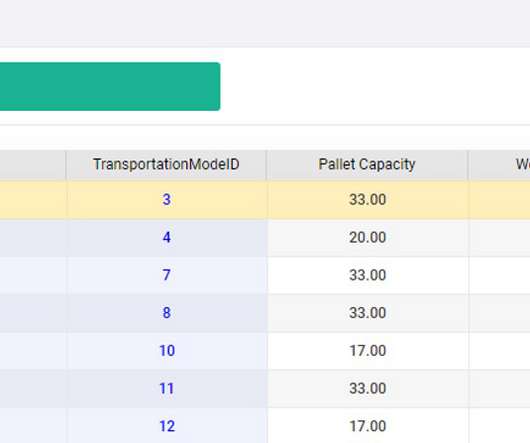

Based on the work with Georgia Tech, we are getting clear on which metrics matter by industry. As companies adopt a balanced scorecard, the functional metrics shift to a focus on reliability. The implementation of NoSQL for inventory management gives them an inventory signal with little to no process latency.

Let's personalize your content