AI in Supply Chain Automation: Procurement to Logistics

Logistics Viewpoints

APRIL 14, 2025

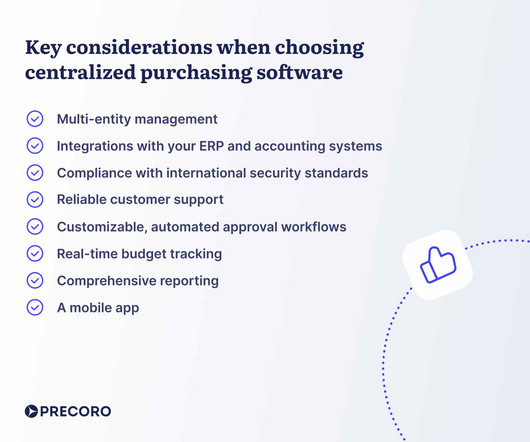

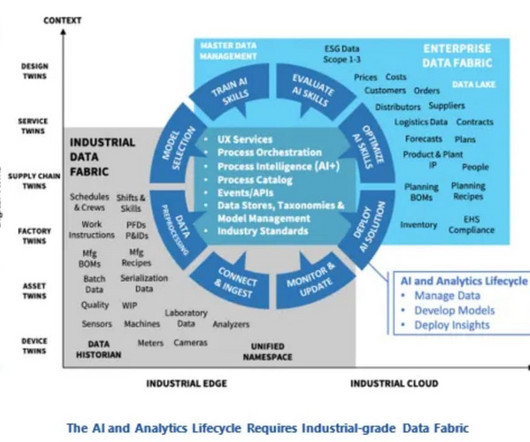

The adoption of AI in supply chain automation is enabling companies to make more accurate decisions, reduce cycle times, and better manage complexity. AI in supply chain automation is gradually reshaping how core functions operate, particularly in procurement, warehousing, and logistics.

Let's personalize your content