Global Supply Chain Disruptions on the Rise

Supply Chain Matters

JULY 26, 2024

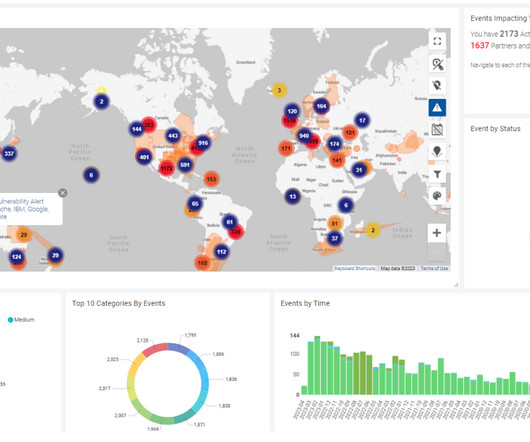

Supply Chain Matters highlights results of a recent survey indicating the level of global supply chain disruptions. Primary Disruption Drivers According to this report , the Resilinc’s EventWatchAI platform has reported in excess of ten thousand supply chain disruptions thus far in 2024.

Let's personalize your content