Intelligent Systems in the Modern Dynamic Warehouse

Logistics Viewpoints

MAY 27, 2025

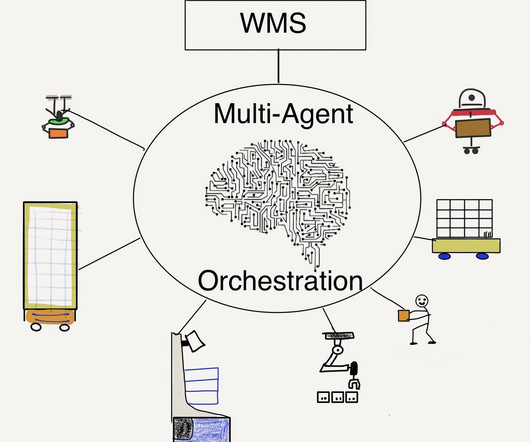

As e-commerce booms, product lifecycles shorten, and labor markets tighten, traditional warehouse management approaches struggle to keep up. Enter the next generation of warehouse optimization – intelligent systems powered by artificial intelligence (AI) and machine learning (ML). What are intelligent warehouse systems?

Let's personalize your content