What is Bullwhip Effect? Supply Chain Management Explained

ThroughPut

MAY 23, 2024

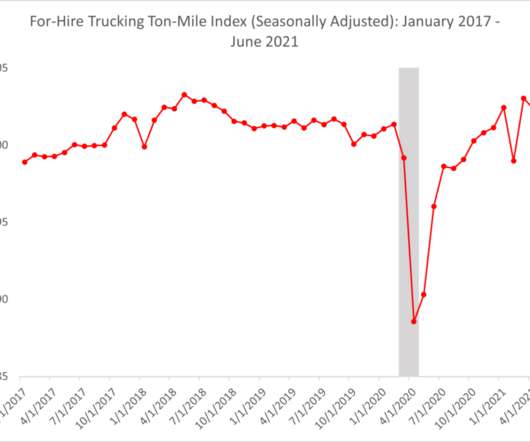

The Bullwhip Effect is a phenomenon where slight fluctuations in demand at the retail level cause progressively larger fluctuations in demand at the wholesale, distributor, and manufacturer levels. Each can lead to increased variability in orders, higher inventory levels, and greater challenges in production planning and capacity management.

Let's personalize your content