Inventory Glut: Strategies and Insights for Modern Retailers

ShipBob

JANUARY 15, 2024

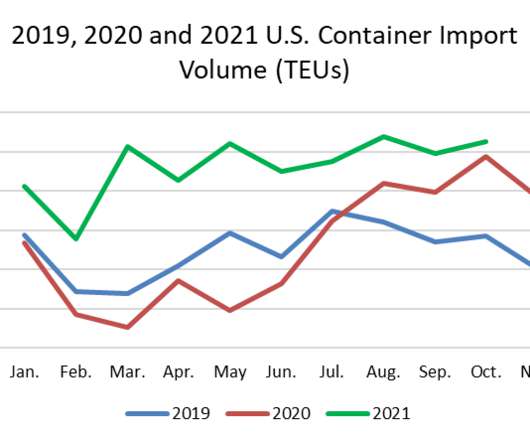

If you don’t have enough inventory on hand you risk selling out. Too much, and you’ll be stuck with an inventory glut. An inventory glut occurs when a company has surplus inventory and the stock of products far exceeds its demand. What is inventory glut? Inventory glut affects businesses both large and small.

Let's personalize your content