Thirteen Years a Blogger

Supply Chain Shaman

FEBRUARY 4, 2025

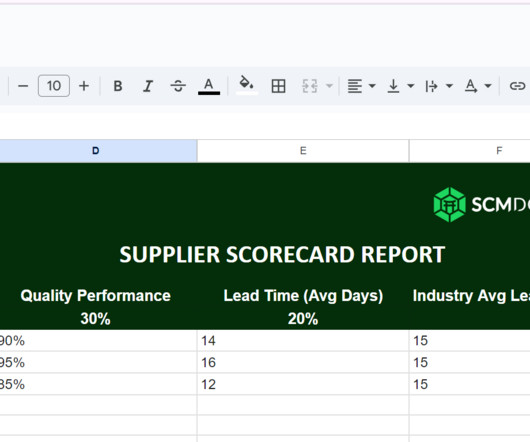

Functional Metrics and the Lack of Alignment to Strategy. Process-based companies continue to focus on manufacturing efficiency (OEE) and discrete on procurement (PPV) without designing the supply chain to balance transportation, manufacturing, and procurement to a balanced scorecard. The Lovefest with Shiny Objects. Guess what?

Let's personalize your content