End-to-End Supply Chain Orchestration: Achieving Visibility and Operational Control

Logistics Viewpoints

MAY 14, 2025

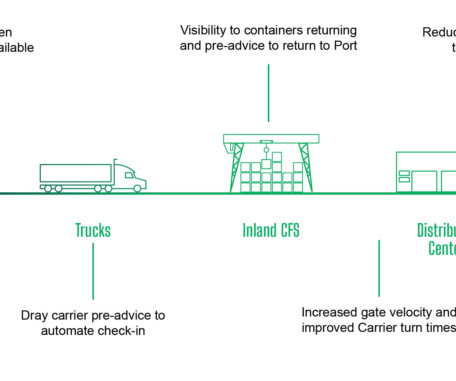

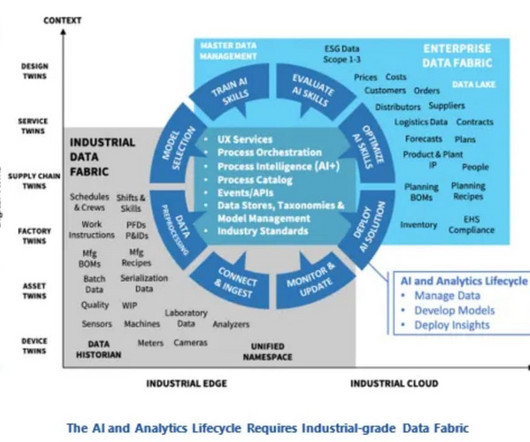

Businesses are now managing goods and information across multiple locations, time zones, and partner networks. This complexity has introduced gaps in visibility and responsiveness that traditional systems werent designed to handle. The factory uses this information to make scheduling and inventory decisions more efficiently.

Let's personalize your content