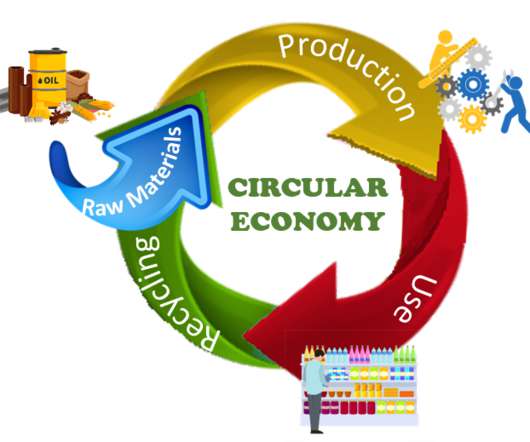

Sustainable procurement: Everything You Need to Know

Precoro

MARCH 31, 2023

March 21 was the second annual iteration of World Sustainable Procurement Day , an online event organized by the Sustainable Procurement Pledge team, SPP Chapters, SPP Champions, and partners to raise awareness about the importance of ethical procurement and to share the best sustainability practices with organizations worldwide.

Let's personalize your content