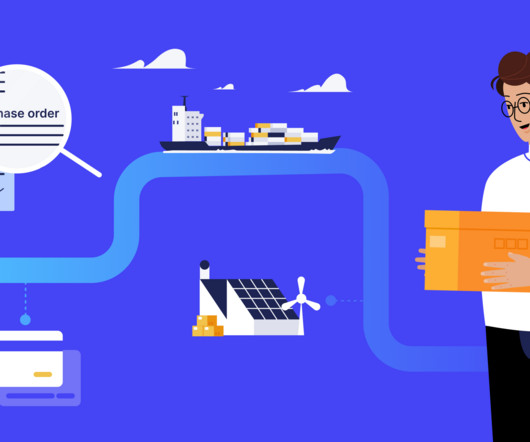

From Siloed to Interconnected: Bring Planning, Sourcing and Procurement Together with a Common Platform

Logility

MAY 25, 2022

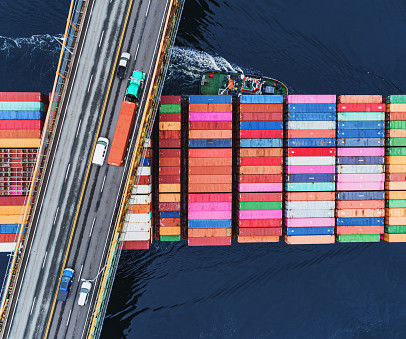

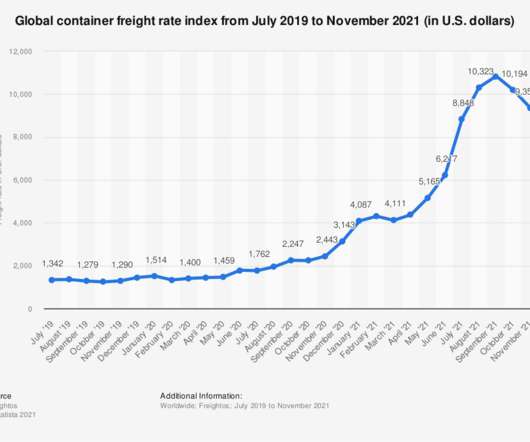

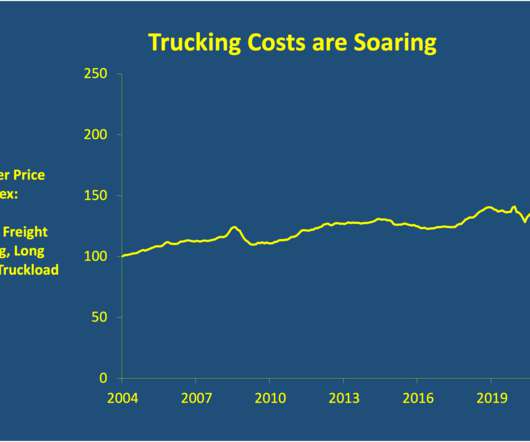

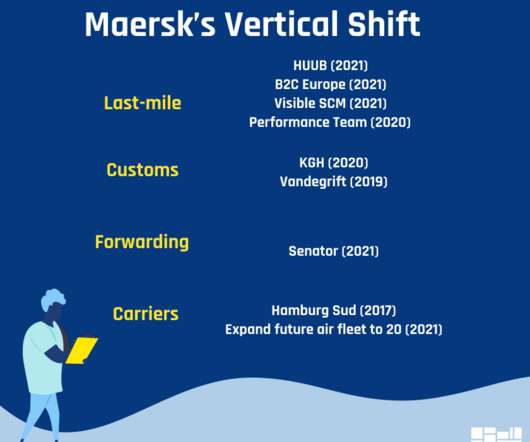

Supply chain organizations are now caught in the clutches of a global economy creaking beneath the weight of cargo embargoes, labor shortages, jammed ports and shipping lanes, and a pandemic that continues to evolve. Manufacturing capacity is severely diminished. Factories run the risk of closing without advanced notice.

Let's personalize your content