4 Tips For Better Process Manufacturing Planning and Forecasting

Logility

OCTOBER 29, 2021

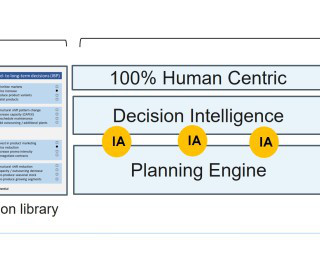

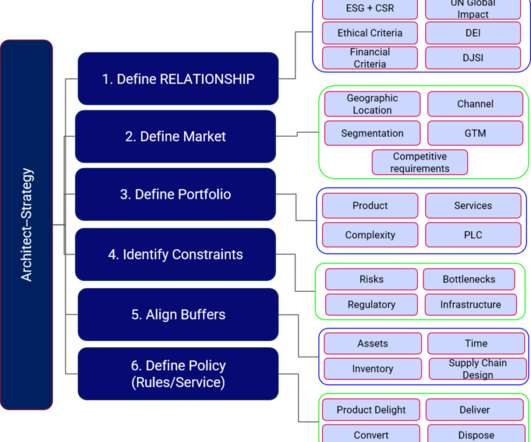

With the right technology, process manufacturing strategy, planning, and management can be simplified. Manufacturers have been through a trial by fire with supply chain disruptions and changes in demand during the past two years. 4 Digital Solutions That Address the Top Challenges for Process Manufacturers.

Let's personalize your content