Pandemic Lessons For Supply Chain Leaders

Supply Chain Shaman

FEBRUARY 18, 2021

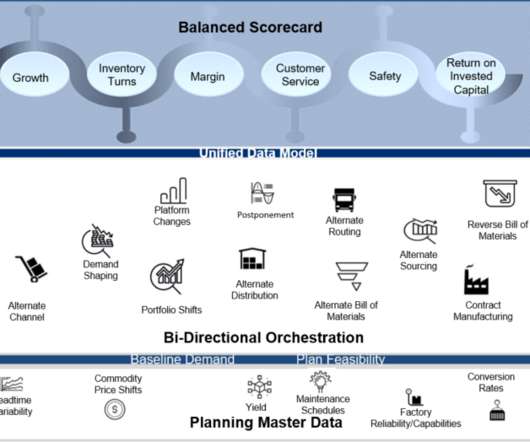

The systems–based on shipment and order data–were out of step with the market. With fixed models and hard-wired data feeds, teams could not adjust the planning systems to use consumption data or market indicators. Initially, the output was published to procurement to design strategic buying strategies. The reason?

Let's personalize your content