ToolsGroup Named a Leader in Quadrant Solutions SPARK Matrix™ for Global Supply Chain Inventory Optimization

ToolsGroup

AUGUST 25, 2022

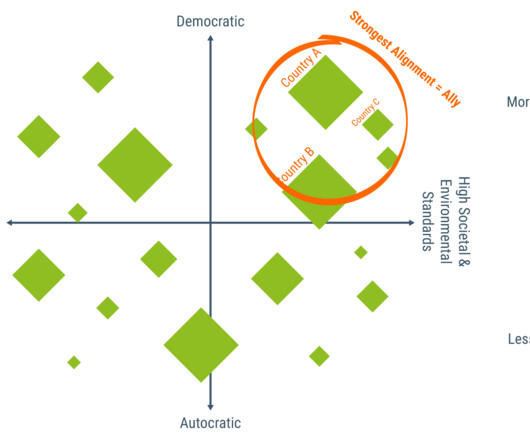

BOSTON – (August 25, 2022) ToolsGroup , a global leader in AI-driven retail and supply chain planning and optimization software, has been named a leader in the Quadrant Solutions SPARK Matrix™ for Global Supply Chain Inventory Optimization. for Global Supply Chain Inventory Optimization, 2022. Source: [link].

Let's personalize your content