Developing Agile Procurement Strategies: Thriving Amid Global Trade Disruptions

Logistics Viewpoints

MARCH 6, 2025

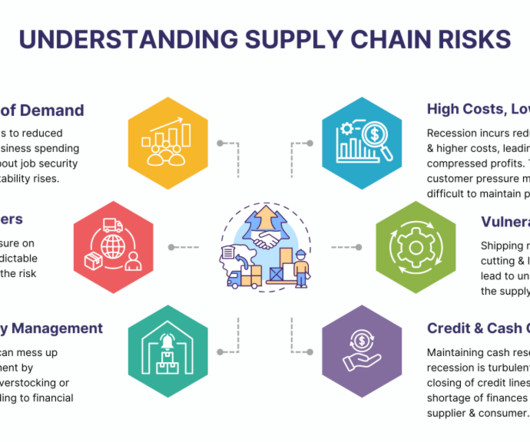

Theyre feeling the heat most, as sudden trade policy curveballs throw procurement plans into chaos. manufacturer I know saw their import costs jump overnight, forcing a rethink of a decade-old sourcing strategy. Traditional procurement, with its long-term contracts and rigid supplier ties, just isnt cutting it anymore.

Let's personalize your content