Tariffs Dominate Dialogue at Gartner SC Symposium in Orlando

AIMMS

MAY 19, 2025

Tariff management means integrating planning, logistics, and technology into a unified supply chain strategy that prioritizes agility and resilience.

This site uses cookies to improve your experience. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country, we will assume you are from the United States. Select your Cookie Settings or view our Privacy Policy and Terms of Use.

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

Used for the proper function of the website

Used for monitoring website traffic and interactions

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

AIMMS

MAY 19, 2025

Tariff management means integrating planning, logistics, and technology into a unified supply chain strategy that prioritizes agility and resilience.

AIMMS

APRIL 8, 2025

The post Introducing SENSAI: Your AI Assistant for SC Navigator appeared first on AIMMS.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

AIMMS

APRIL 2, 2025

Companies that use scenario modeling, network design studies, and location risk analysis are better positioned to navigate tariff disruptions.

AIMMS

MARCH 28, 2025

These updates to SC Navigator tackle key supply chain design needs, from scenario planning to data integration and transport management.

AIMMS

MARCH 25, 2025

What makes center of gravity analysis a cornerstone of any supply chain network optimization strategy? Find answers from best practices.

AIMMS

MARCH 10, 2025

As new policies shape the new now, scenario planning becomes a key tool for supply chain leaders to anticipate changes, mitigate risks etc.

AIMMS

MARCH 3, 2025

Introducing SC Navigator ETL (Extract, Transform & Load), a powerful tool designed to automate and streamline your data preparation process.

AIMMS

FEBRUARY 26, 2025

To tackle their supply chain challenges, leading data center companies turn to advanced supply chain design and optimization software.

AIMMS

FEBRUARY 18, 2025

Mergers and acquisitions (M&A) are powerful strategic tools for growth, but their success hinges on the seamless integration of supply chains.

AIMMS

FEBRUARY 3, 2025

Discover how Power BI Embedded in SC Navigator empowers you to create custom reports, visualize scenario data, and make data-driven decisions.

AIMMS

JANUARY 8, 2025

Discover how Hyperscaling in AIMMS SC Navigator boosts productivity by solving multiple scenarios in parallel.

AIMMS

JANUARY 3, 2025

Overcome network design challenges with AIMMS SC Navigator. Learn how this easy-to-use application simplifies adoption and delivers measurable results.

AIMMS

DECEMBER 18, 2024

For supply chain leaders in the EU, particularly in energy industries (EIIs), these threats likely demand a proactive, strategic approach.

AIMMS

DECEMBER 5, 2024

Scenario Navigator supports the creation of sub-scenarios. It is designed to make supply chain analysis smarter, faster, and more structured.

AIMMS

OCTOBER 17, 2024

Network design solves a variety of issues, from cost reduction to sustainability, and from inventory optimization to investment decisions.

AIMMS

OCTOBER 14, 2024

Supply chain optimization is now a strategic priority that directly affects profit, competitiveness, resilience and long-term sustainability.

AIMMS

SEPTEMBER 9, 2024

Network design technology plays a pivotal role in enhancing the efficiency and effectiveness of long-range capacity planning.

AIMMS

AUGUST 28, 2024

Probabilistic planning in supply chains involves systematically analyzing scenarios for each business objective to account for uncertainty.

AIMMS

AUGUST 16, 2024

The three user roles in SC Navigator - the modeler, analyst, and consumer encapsulate a streamlined process for data-driven decision-making.

AIMMS

AUGUST 14, 2024

Our network design data model is designed around Supply Chain entities you will recognize, customers, warehouses, suppliers, production and transport lanes.

AIMMS

JULY 23, 2024

An example of a top strategic shift is adopting a more agile and iterative approach to supply chain optimization supported by technology.

AIMMS

JULY 2, 2024

Discover SC Navigator’s upgraded Center of Gravity functionality. See how Constrained CoG and Trade-Off Analysis can optimize network design.

AIMMS

JUNE 20, 2024

With AIMMS, Heineken continues to advance its supply chain planning capabilities, achieving greater efficiency and sustainability.

AIMMS

MAY 31, 2024

Learn how advanced constraints can optimize your supply chain by constraining elements like warehouses and suppliers and improving efficiency

AIMMS

MAY 22, 2024

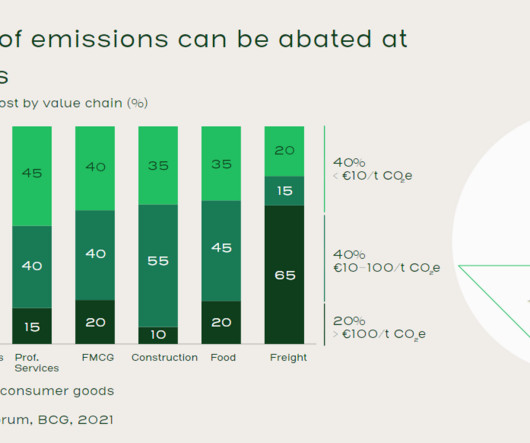

Global supply chain leaders are increasingly recognizing the importance of establishing in-house sustainability expertise.

AIMMS

APRIL 23, 2024

Consumers may be willing to pay 2% to 10% more for products from vendors that provide greater supply chain network transparency.

AIMMS

APRIL 10, 2024

The power of AIMMS in the field of mathematical optimization is undeniable. Our new users shared their experiences using AIMMS.

AIMMS

MARCH 8, 2024

Supply chain network design explained. A guide through the implementation process, analytics, optimization tech, and sustainability impact.

AIMMS

FEBRUARY 27, 2024

SC Navigator's new Whiteboard functionality visually maps supply chains, simplifying data input for efficient modeling.

AIMMS

FEBRUARY 15, 2024

Optimize inventory, resources, and customer fulfillment in your supply chain network with AIMMS SC Navigator's new module Tactical Planning.

AIMMS

FEBRUARY 6, 2024

Learn how much revenue could a global supply chain lose and how can a supply chain leader adapt to prevent their impact.

AIMMS

FEBRUARY 2, 2024

AIMMS Math Program Inspector presents a visual and streamlined approach, empowering developers to comprehend and traverse models with ease.

AIMMS

JANUARY 12, 2024

AIMMS SC Navigator optimizes Brazilian supply chains, offering unique functionality to handle refundable taxes within the country's tax framework

AIMMS

DECEMBER 18, 2023

The post How can the Carbon Border Adjustment Mechanism (CBAM) trigger a redesign of your supply chain network? appeared first on AIMMS.

AIMMS

NOVEMBER 27, 2023

In a future where a supply chain planner collaborates with AI, the fusion of technology and human expertise enables strategic planning and execution.

AIMMS

OCTOBER 17, 2023

Sustainable supply chains are not just beneficial for society and the environment; they’re crucial for a business’s future prosperity. This is because such chains influence capital acquisition, regulatory compliance, and customer loyalty. Big investment decisions that touch the core supply chain are always hard to make, especially if the returns are not quick.

AIMMS

OCTOBER 10, 2023

With the new Backhaul feature, supply chain teams can actively reduce mileage, carbon emissions, and costs, while optimizing reverse flows.

AIMMS

OCTOBER 6, 2023

Let's debunk AIMMS and Python misconceptions, highlighting AIMMS' potential for mathematical optimization-powered business apps.

AIMMS

SEPTEMBER 15, 2023

Optimized network design relies on data. But how to source and format this data for supply chain design technology? Read the blog to learn.

AIMMS

AUGUST 28, 2023

The post The Role of Greenfield Analysis in Modern Supply Chain Design appeared first on AIMMS.

AIMMS

AUGUST 25, 2023

Improving supply chain resilience is the focus for global retail brands with complex supply chain network design.

AIMMS

AUGUST 1, 2023

AIMMS Connect Week is about starting with ourselves, to reinforce our purpose-driven and self-organized work culture.

AIMMS

JULY 24, 2023

Ready to optimize your supply chain operations like BASF? Explore the potential of SC Navigator and take your operations to new heights.

AIMMS

JULY 19, 2023

Product segmentation strategies trigger leaders to rethink their supply chain optimization plans, by focusing on cost-efficiency, service, and sustainability.

Expert insights. Personalized for you.

Are you sure you want to cancel your subscriptions?

Let's personalize your content