Spare Parts to Profits: Strategic Inventory Mastery

ToolsGroup

OCTOBER 14, 2024

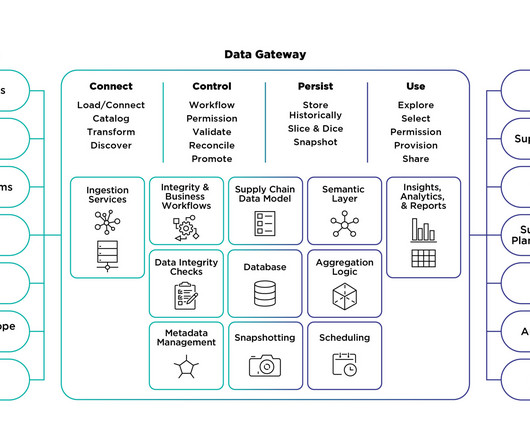

In the competitive industrial landscape, efficient spare parts inventory management is crucial to maintaining seamless operations and driving profitability. Organizations require robust inventory management systems capable of handling diverse parts throughout their lifecycle.

Let's personalize your content