One Multinational’s Supply Chain Transformation Journey

Logistics Viewpoints

APRIL 4, 2022

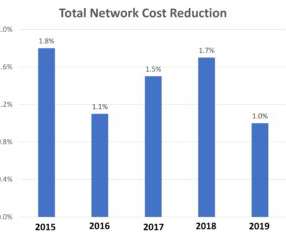

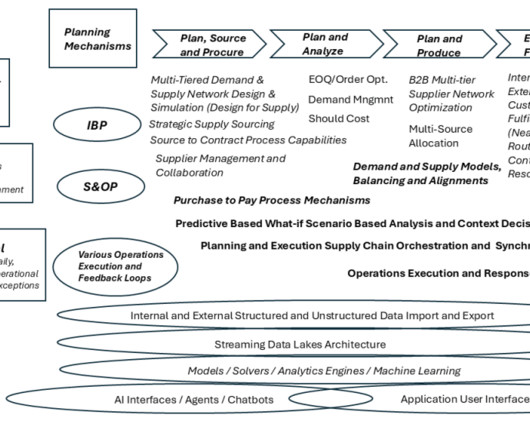

A large multinational is undergoing an impressive supply chain transformation that will run through 2023. A Complex Supply Chain. Not surprisingly a company this big, delivering different solutions to a variety of industries, has a complex supply chain. A Transformation Journey.

Let's personalize your content