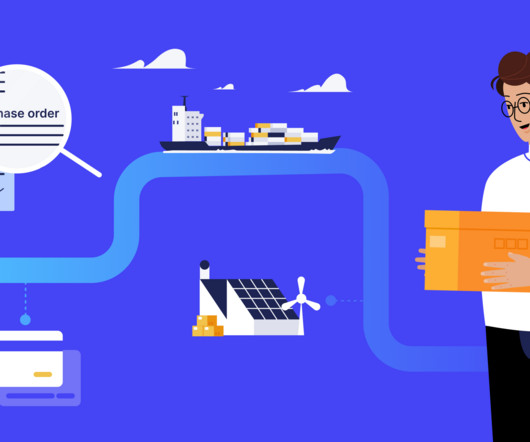

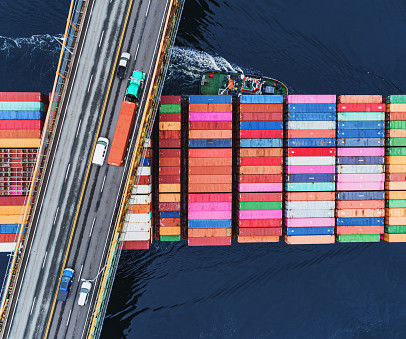

Sourcing And The Value Chain – Why Digital Platforms Matter

Gravity Supply Chain

FEBRUARY 27, 2020

Real time predictive analytics ensure offshore and nearshore sourcing decisions take place with certainty. The post Sourcing And The Value Chain – Why Digital Platforms Matter appeared first on Gravity Supply Chain. Gravity’s technology helps mitigate risk.

Let's personalize your content