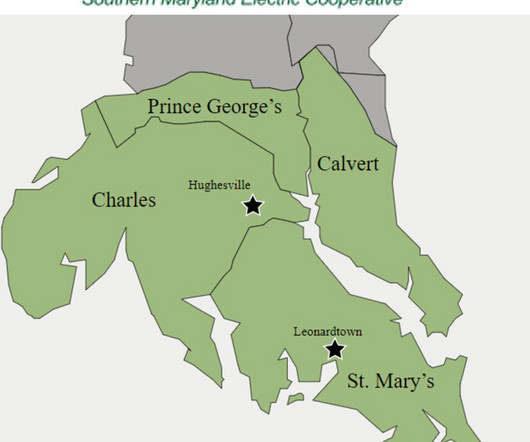

Southern Maryland Electric Cooperative Tackles Warehouse Complexity

Logistics Viewpoints

APRIL 12, 2023

For example, instead of traditional longitude latitude coordinates, electric power distribution companies often use approaches such as linear referencing and network connectivity to describe asset context and attributes. The organization is using Hitachi Ellipse as its enterprise asset management system (EAM).

Let's personalize your content