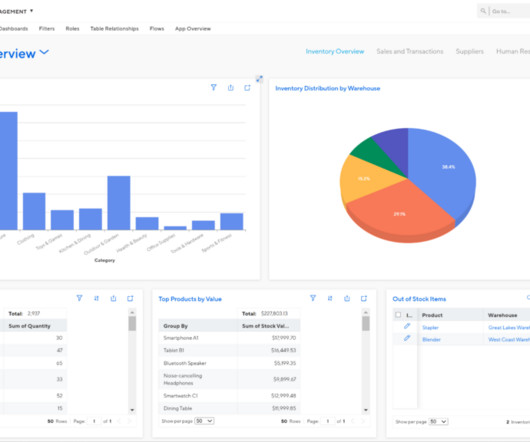

TrackVia’s Exceptional Inventory Management Capabilities

TrackVia

MAY 25, 2023

Many companies are realizing the critical role that effective inventory management plays in streamlining warehouse operations and maintaining an edge over competitors. Check out how UC San Diego improved their inventory and asset management processes.

Let's personalize your content