Why Procurement Professionals Should Learn About S&OP

SCMDOJO

OCTOBER 28, 2024

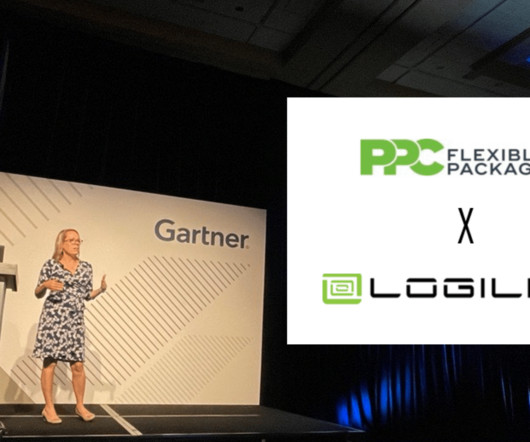

Sales & Operations Planning (S&OP) is an established industry process that aims at finding a balance between demand and supply and streamlining cross-functional collaboration. Procurement People should learn the Sales & Operations Planning (S&OP) Process. Click here to learn more and register today!

Let's personalize your content