Supply Chain & Logistics News January 2nd-6th 2025

Logistics Viewpoints

FEBRUARY 7, 2025

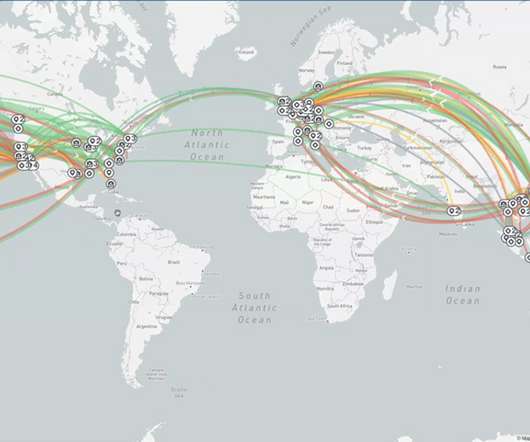

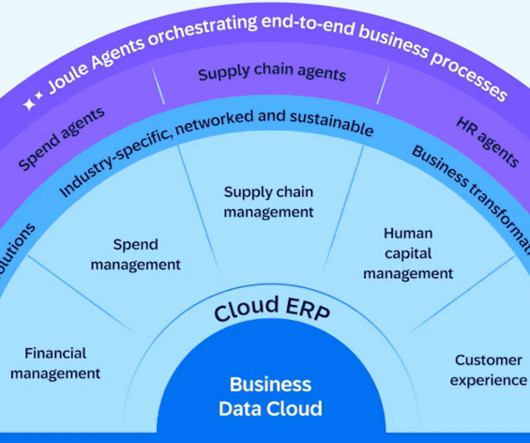

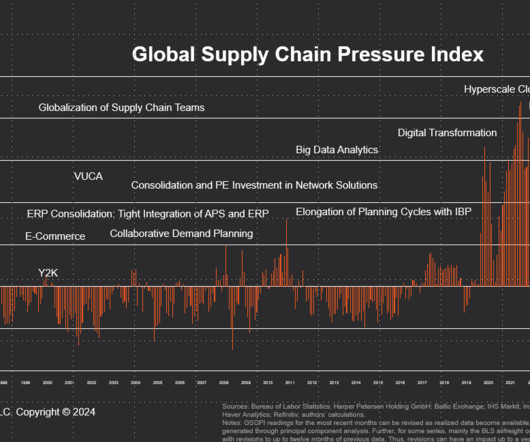

Supply Chain & Logistics News January 2nd-6th 2025 The global supply chain never sleeps, and this weeks headlines reveal the fast-moving shifts shaping logistics, trade, and technology. These passports provide a digital way to document a products entire lifecycle, ensuring compliance and transparency.

Let's personalize your content