Metrics that Matter: Inventory Effectiveness

QAD

JUNE 25, 2019

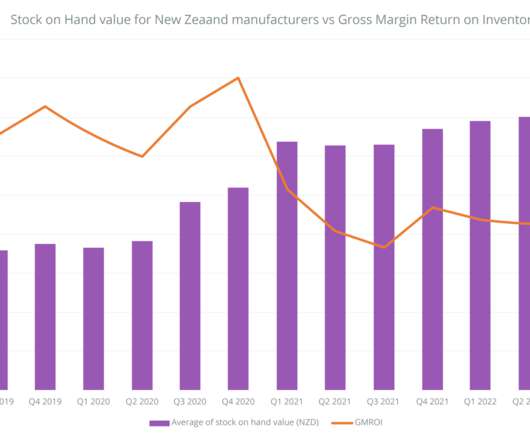

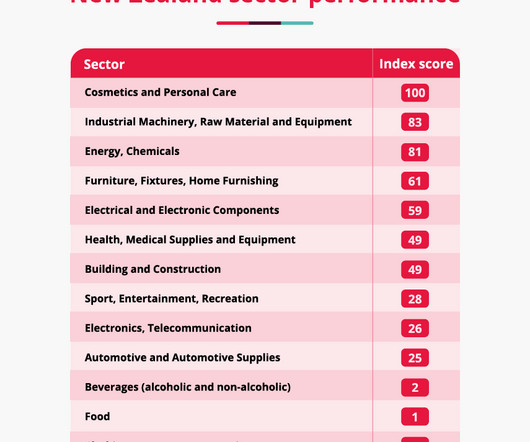

The effective use of a manufacturer’s inventory investment is an important determinant of the company’s success. Excess and obsolete inventory is a drain on resources, as is excessive safety stock. Managing an Inventory Investment. Managing an Inventory Investment. Using Metrics to Measure the Health of the Business.

Let's personalize your content