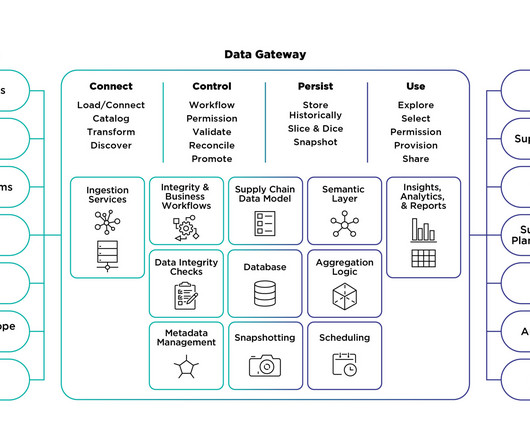

10 Ways A Data Gateway Improves Time to Value Across Your End-to-End Supply Chain

Logistics Viewpoints

MARCH 11, 2025

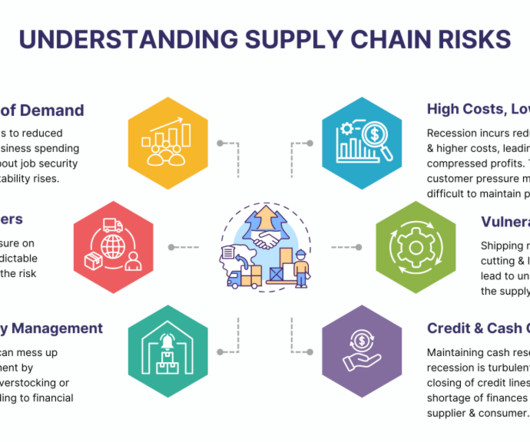

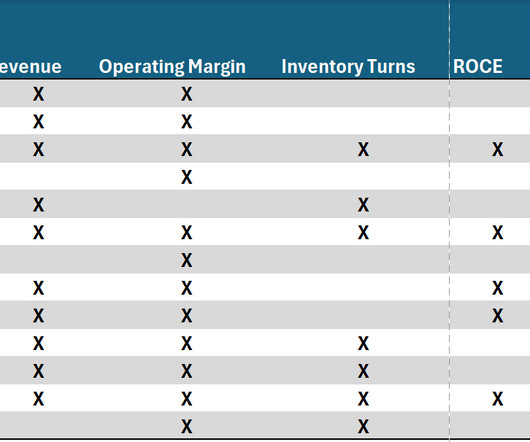

Enables You to Identify Inefficiencies and Make Better and Informed Decisions A unified view of your data accelerates informed decision making and provides you with a comprehensive understanding of your supply chain. Here are 10 ways a supply chain data gateway can improve your performance across the end-to-end supply chain.

Let's personalize your content