The Industrial Internet of Things, Manufacturing, Supply Chain & Logistics: Where Are We & Where Are We Going?

GlobalTranz

NOVEMBER 9, 2016

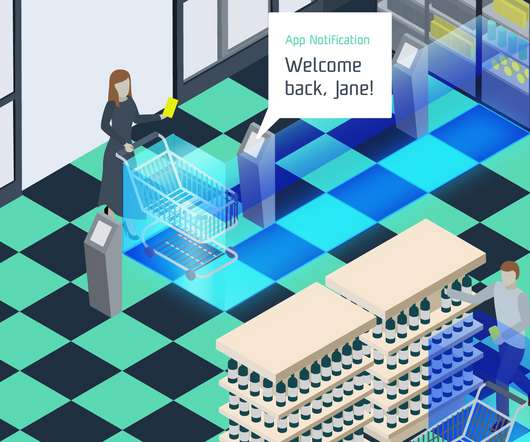

In place of long paper trails and maintenance schedules, machines with the capacity to communicate their needs and issues via the industrial Internet of Things (IoT) are becoming an essential component of effective processes. Warehouse Management. Transportation Management.

Let's personalize your content