Smart Manufacturing Trends to Expect in 2024

OptiProERP

NOVEMBER 22, 2023

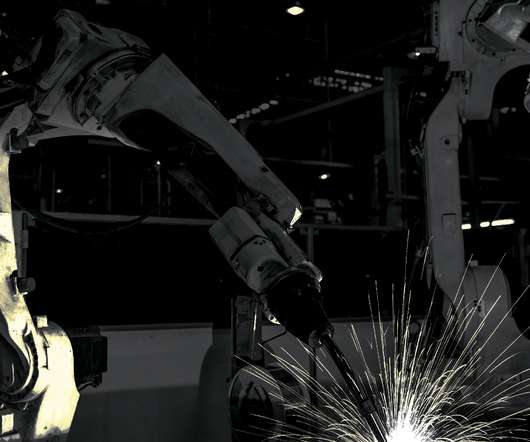

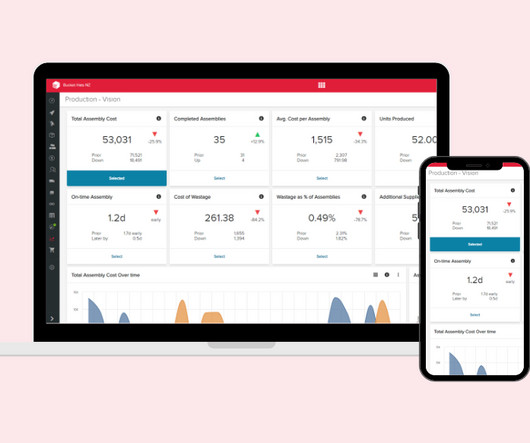

With 2024 on the horizon, more manufacturers are adopting smart manufacturing technology. It is helping them capture benefits across the entire manufacturing value chain. Examples of intelligent factories include on-demand manufacturing and virtual inventories.

Let's personalize your content