Spare Parts to Profits: Strategic Inventory Mastery

ToolsGroup

OCTOBER 14, 2024

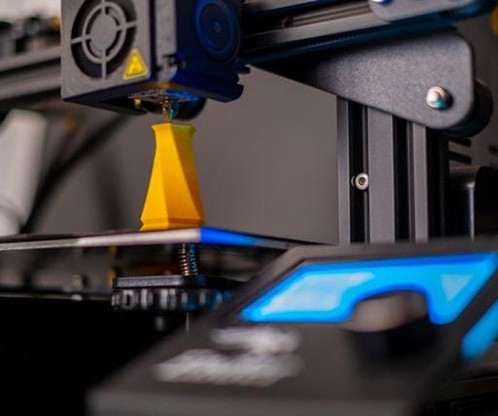

In the competitive industrial landscape, efficient spare parts inventory management is crucial to maintaining seamless operations and driving profitability. Spare parts supply chains, however, come with their own set of complexities, requiring targeted strategies and specialized tools to meet these unique demands effectively.

Let's personalize your content