Omnichannel Retailers Leverage Optimization for Order-Promising

Logistics Viewpoints

JANUARY 1, 2024

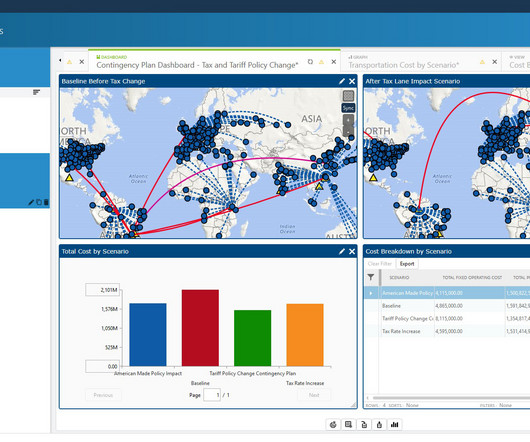

Historically, omnichannel software solutions were not capable of optimization. They can also order online and have goods shipped to their home. Historically, an OOM has access to all the company’s inventory. The system allocated which orders would get inventory from a given location to fulfill an order. That is changing.

Let's personalize your content