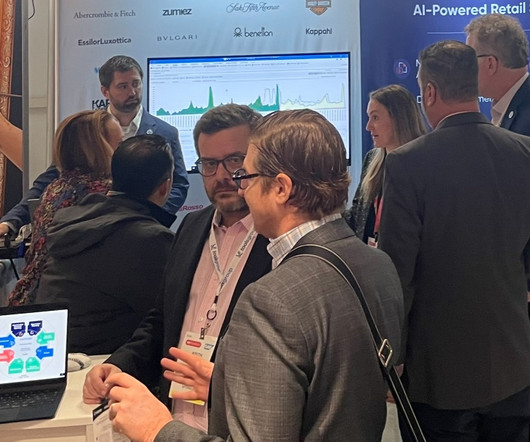

ToolsGroup Launches Integrated In-Season Retail Inventory Optimization Solution

ToolsGroup

JANUARY 15, 2024

Retailers can now quickly sense, predict, and respond to real-time changes in demand to better navigate market uncertainty to achieve maximum profitability. Retailers today need an integrated solution that is agile enough to adapt to even the smallest changes in demand.”

Let's personalize your content