Truck Parking Club doubles network in under 6 months

Freight Waves

JUNE 5, 2025

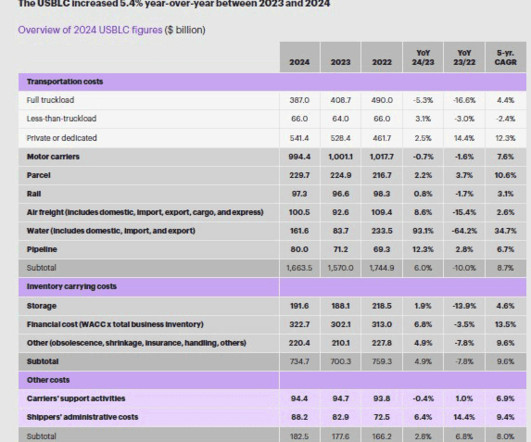

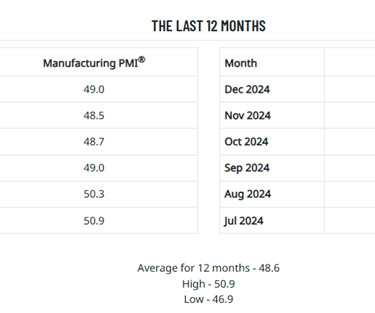

Chattanooga, Tennessee-based Truck Parking Club recently announced it has surpassed 2,000 property member locations nationwide, a doubling of its footprint in six months. The m/m increase was impacted by inventories, which saw higher costs and slower movement compared to earlier in the year. The May LMI came in at 59.4 points, up 0.6

Let's personalize your content