Modern TMS Solutions: Driving Sustainability in Supply Chain Operations

Logistics Viewpoints

DECEMBER 17, 2024

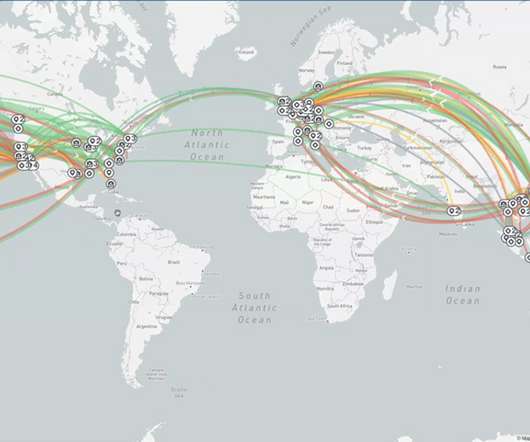

However, as carbon taxes and emissions reporting requirements continue increasing, supply chain professionals face mounting pressures from inside and outside their organizations to measure and improve performance against new, nebulous sustainability metrics. Freight transportation makes up over 10% of total global carbon emissions.

Let's personalize your content