Scaling a FreightTech Business with Mark McEntire

The Logistics of Logistics

DECEMBER 1, 2023

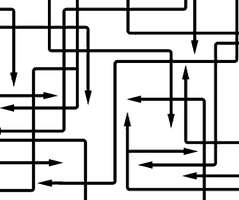

Mark is the Chief Executive Officer off Princeton TMX , a SaaS-based transportation management system (TMS). About Mark McEntire Mark McEntire is the Chief Executive Officer at Princeton TMX, a SaaS-based transportation management system (TMS). Hunt Transport, Inc. in Transportation and Logistics from Arkansas State University.

Let's personalize your content