Next Level Apparel® Takes its Demand and Inventory Planning to the Next Level with the Logility® Digital Supply Chain Platform

Logility

APRIL 26, 2022

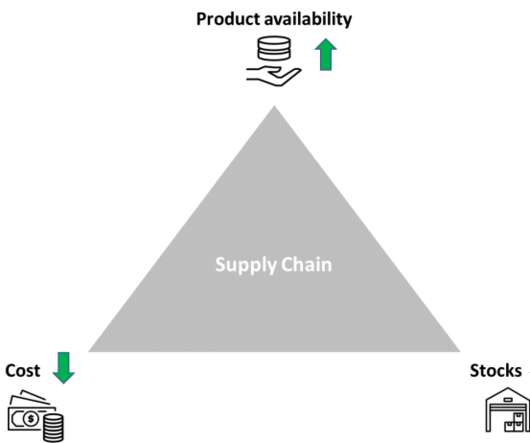

based supplier of fashion blanks transforms its demand and inventory management with Logility. One of the leading wholesale producers and sellers of premium quality blank apparel in the United States, Next Level Apparel has implemented the Logility® Digital Supply Chain Platform to modernize its demand and inventory planning processes.

Let's personalize your content