When We Don’t Have Answers, We Need to Work Quickly To Build Them

Supply Chain Shaman

OCTOBER 5, 2021

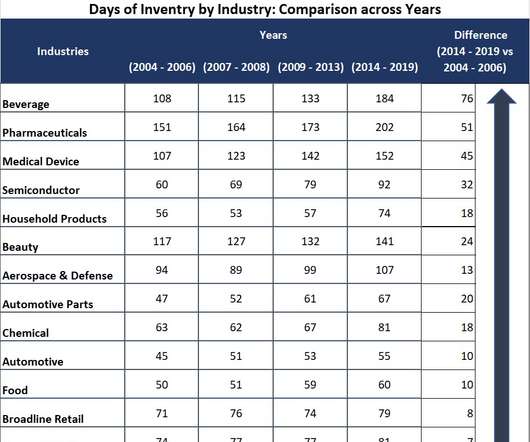

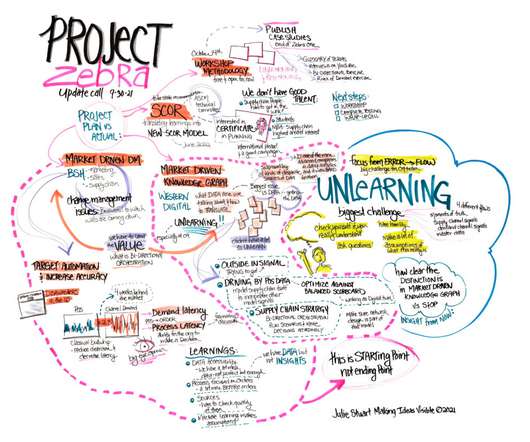

To drive progressive change, I think that we need to rethink supply chain basics and unlearn from the past while driving process innovation. Let’s Start With a Discussion on Inventory. When we look at table 1, we see burgeoning inventories in some industries and extreme shortages in others. The end result? The reason?

Let's personalize your content