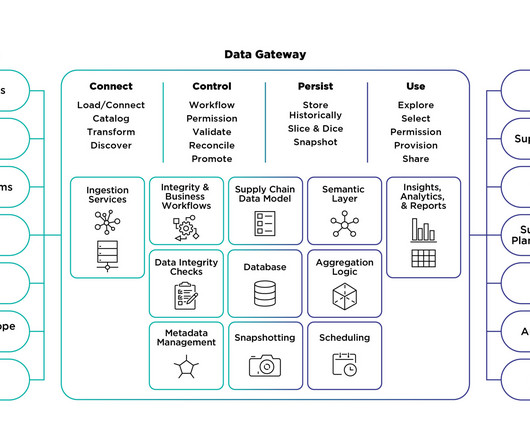

10 Ways A Data Gateway Improves Time to Value Across Your End-to-End Supply Chain

Logistics Viewpoints

MARCH 11, 2025

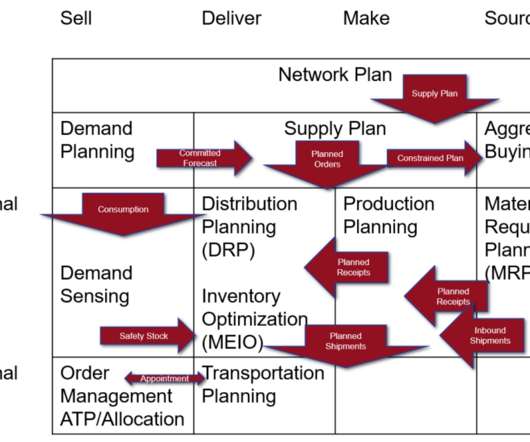

Supply chain practitioners seeking the best way to speed decision intelligence, unify supply chain data, and increase operational efficiency can benefit from a supply chain data gateway. Here are 10 ways a supply chain data gateway can improve your performance across the end-to-end supply chain.

Let's personalize your content