From Siloed to Interconnected: Bring Planning, Sourcing and Procurement Together with a Common Platform

Logility

MAY 25, 2022

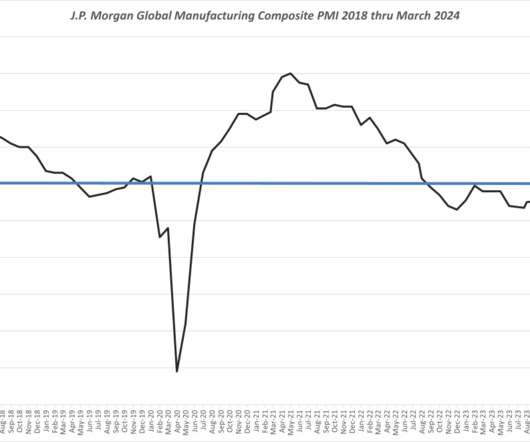

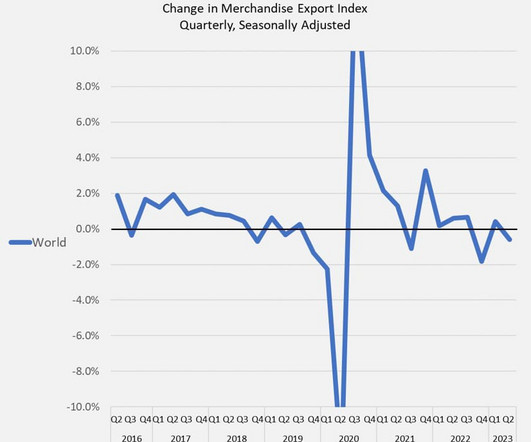

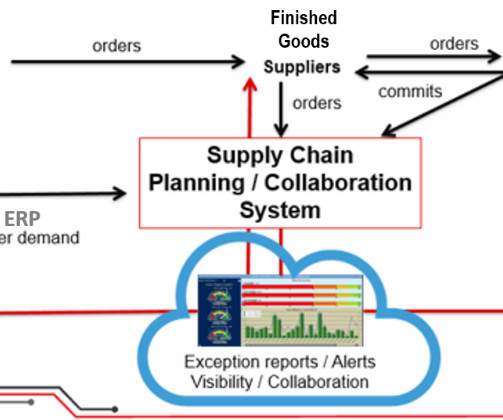

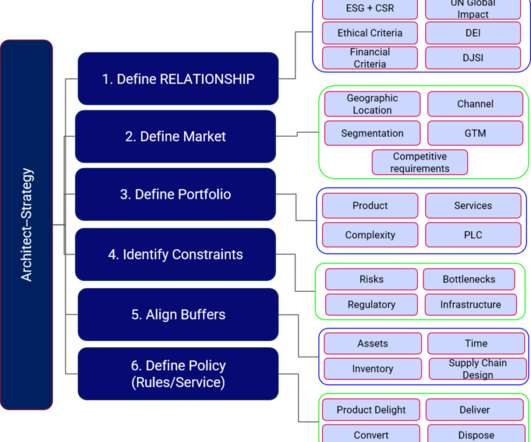

Manufacturing capacity is severely diminished. Now more than ever, the conventional silos of planning, sourcing, and procurement teams must be connected into one cohesive network. For example, an operations planner can dig into internal capacity data stored on the cloud ? Let’s face it ? What Needs to Change?

Let's personalize your content