Introducing Freightos Enterprise: End-to-End Procurement, Benchmarking, and Management

Freightos

APRIL 23, 2025

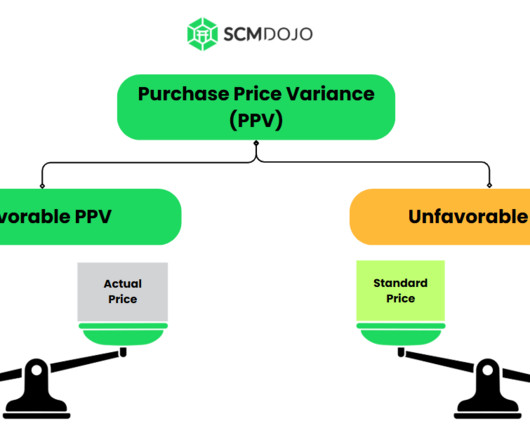

Home Introducing Freightos Enterprise: End-to-End Procurement, Benchmarking, and Management Freightos Enterprise unifies market intelligence, tender management, and shipment operations into one solution, enhancing logistics efficiency for large import-export businesses.

Let's personalize your content