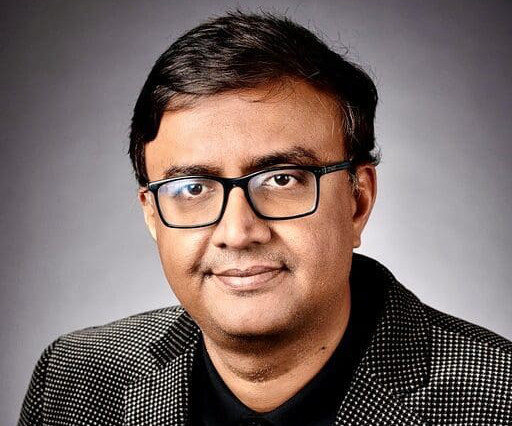

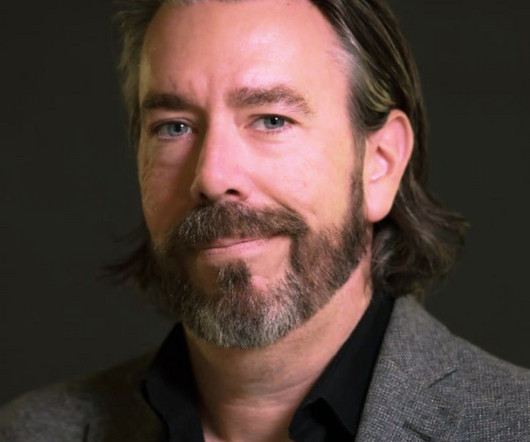

OneRail’s Winning Strategy for Final Mile with Bill Catania

The Logistics of Logistics

JANUARY 7, 2025

Bill Catania and Joe Lynch discuss OneRail’s winning strategy for final mile. By optimizing fulfillment processes, reducing costs and improving order accuracy, OneRail is committed to empowering clients and improving the customer experience. To learn more about OneRail, visit OneRail.com.

Let's personalize your content