Advanced Supply Chain Planning with Probabilistic Forecasting

ToolsGroup

MARCH 31, 2025

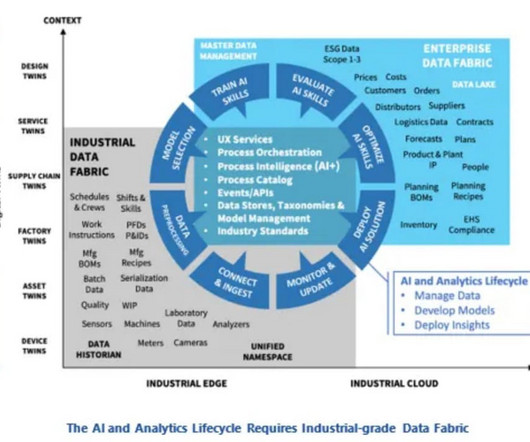

In the fast-paced world of modern supply chains, traditional forecasting methods fall short. Advanced supply chain planning is being transformed by probabilistic forecasting , which revolutionizes demand forecasting, supply planning, and inventory optimization.

Let's personalize your content