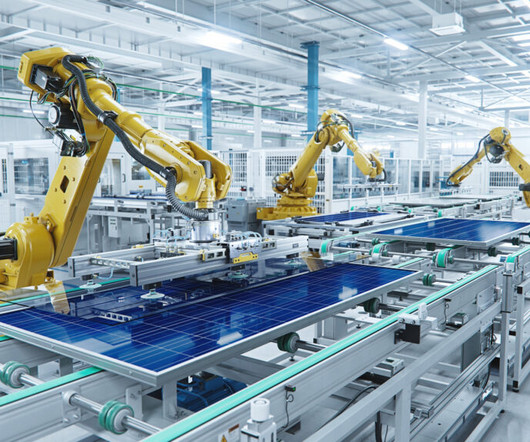

AI in Supply Chain Automation: Procurement to Logistics

Logistics Viewpoints

APRIL 14, 2025

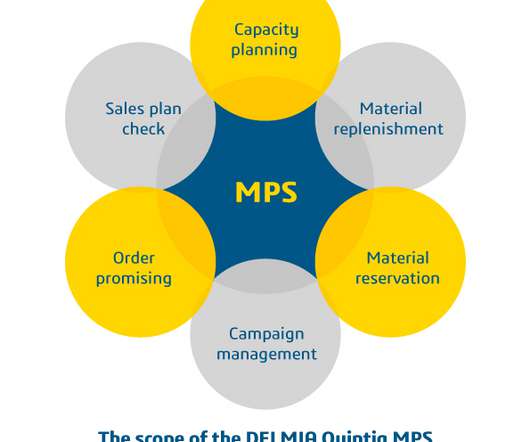

AI in supply chain automation is gradually reshaping how core functions operate, particularly in procurement, warehousing, and logistics. Key Insight: The use of AI in supply chain automation is producing tangible benefits across procurement, warehousing, and logistics.

Let's personalize your content