Digital Transformation in Logistics

Logistics Viewpoints

APRIL 5, 2023

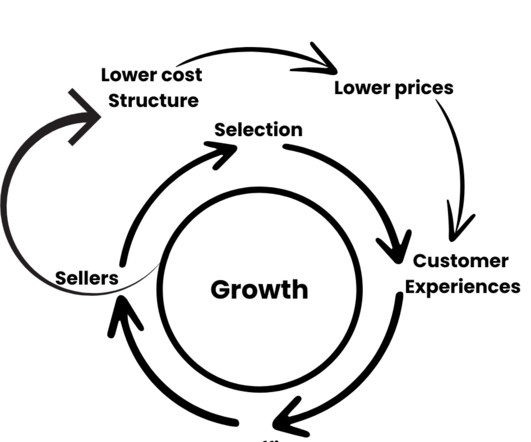

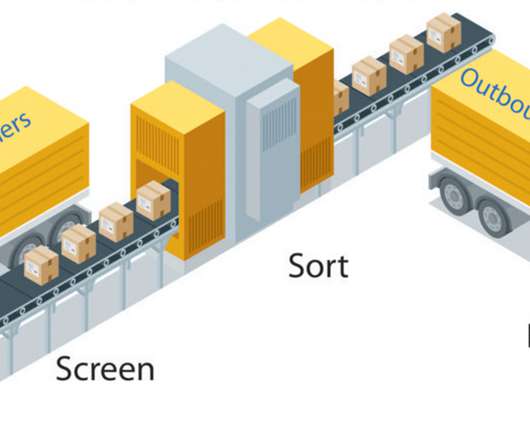

Design and engineering, production operations, maintenance, logistics, supply chain, business systems, customers, products, and organizational structure are subject to innovative change as companies examine and update processes and deploy new tools and technologies.” There are many areas of digital transformation within the supply chain.

Let's personalize your content