Top Supply Chain Planning Vendors Are Investing to Support Agile Planning

Logistics Viewpoints

DECEMBER 30, 2024

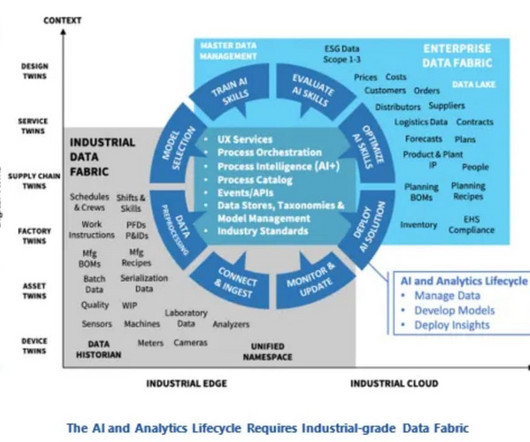

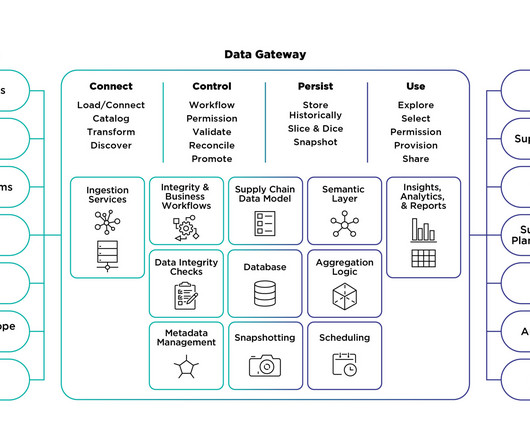

Digital Twin Screen Shot and Architecture The most comprehensive form of planning that companies engage in is integrated business planning. Based on this, a multiple-month financial, supply chain, and capital expenditure plan is produced. This realization led to a new focus on agile planning.

Let's personalize your content