Managing cost, quality and traceability in fabricated metals manufacturing

SYSPRO Smarter ERP

OCTOBER 9, 2023

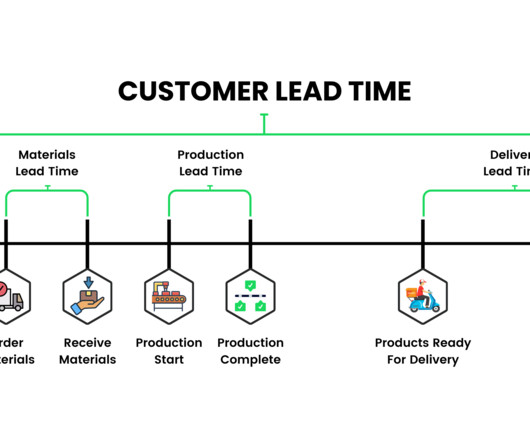

The Asia-Pacific region has one of the largest number of fabricated metals manufacturers in the world. Cost efficiency, quality management and traceability are major issues for companies in this region. Many governments are also offering incentives for manufacturers to invest in energy-efficient solutions.

Let's personalize your content